The hills are alive with the sound of cowbells

I had the pleasure of being invited to Austria, by smoked cheese experts Rupp, to find out how their cheese is made and see where the milk comes from. The Austrian Alps are in the heart of Europe and are stunning location to visit at any time.

We were visiting the “Alpe Obere” dairy to meet the family, the cows, and see behind the scenes at cheese-making and find out how the Alps and cheese are entwined. The drive up was a bit scary – a road with passing places, which isn’t so good when you are looking down thousands of meters! However, as you can see: stunning scenery! This was one of the buildings we passed on the way up.

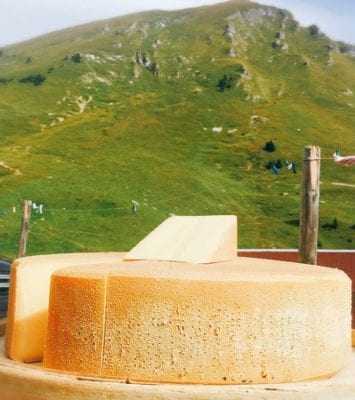

We reached the top, came out of the cars and saw this, wow!

On the left, you have the winter barn and a view across the valley.

The Vorarlerg area has around 105,000 hectares of feeding area with approximately 40,000 head of cattle summer here. This equates to 526 working alpine farms, around 150 dairies, where 450,000 kilogrammes of alpine cheese! In 2008, the Slow Food Bregenzerwald Bergkäse was added to its “Ark of Taste”.

We were here to see “Alpere Obere” which stands at 1,593m above sea level, quite a height! This area is the largest hay milk area in Europe. Hay milk means that the animals graze on meadows, pastures and mountain pastures in the summer and are fed hay in the winter. This gives the milk a unique taste and quality. The cows don’t feed on silage.

Farming on alpine dairies is a family affair. The farms are passed through the generations and at Alpere Obere we met Barbara and Herbert Rüf with their 3 children. Working every day, tending the cows and making cheese. The farms are generally open to the public as many people hike up the Alps and stop off at the farms to eat, drink and possibly stay overnight.

Alpere Obere farming and Rupp cheese

Alpere Obere have 82 cows, 45 Alpine pigs, 5 goats and 7 chicken! That’s a lot of work to start with, never mind cheese-making and looking after bloggers! We covered ourselves up and headed inside to see the cheese making in progress.

The milk is heated in traditional wood-fired pots. The fire was carefully tended to keep the milk at optimum cheese-making temperature.

Once the curds were ready to be strained, Herbert took his trusty cheese cloth and hand-strained just the right about for each cheese mould. He must have asbestos hands!

And er, strong teeth too! Health & Safety wouldn’t allow this in the UK would it?!

Luckily he didn’t Rupp-ture it (groan!)

The curds are then placed into moulds and squashed into shape.

Then they are labelled / stickered. “Hergestellt auf Alpe” means “made in the Alps”.

Once the whey has drained off the cheese is ready to be moved into storage to mature.

Not all the milk goes to make cheese, there is also delicious butter. Have you ever tried Austrian butter? Probably the nearest we can buy in the UK, which tastes as creamy is Kerrygold. But if you see Austrian or German butter on your travels, do try some!

I loved the butter moulds, so simple and delicate.

If I had luggage space for butter, I would have brought all of this back!

Smoking Cheese

A temporary smoker was built to show us how smoked cheese is made. Smoking preserves items, so smoked cheese could be kept throughout winter in the time before fridges. Austrian smoked cheese is made by placing the cheese above smoking wood for a mild flavour. In the supermarkets you will notice the brown-rinded Bavarian smoked cheese.

This cheese is placed in a 70°C hot smoking chamber over beechwood for 2-3 hours. It takes time to get that smokey taste and creamy interior. This cheese is soft and smooth and can be easily sliced.

After all that it was time to sample the home-smoked cheese and wash it down with a local radler on the terrace (not a bad view eh?).

Thanks to these ladies and to Rupp for showing me behind the scenes at an alpine dairy.

Find out more about Rupp Cheese HERE.

Disclaimer: Mrs Foodie was given a free tour and transport to see behind the scenes cheese-making at Rupp Cheese.